Quikec Products

Our products make use of AI, big data, cloud and patented smart devices to ease & add value to QA and QC activities along the B2B supply chain.

QuikMicroscopic

This AI technology provides Food and Beverages (F&B) industry “image recognition” capabilities to automate micro-organism identification in the Plate Count Agar process for product quality control. Microscopic images of the cultures uploaded to the Quikec platform automatically identify and quantify the micro-organisms.

Why Quikec?

Our goal is to help with your pain points.

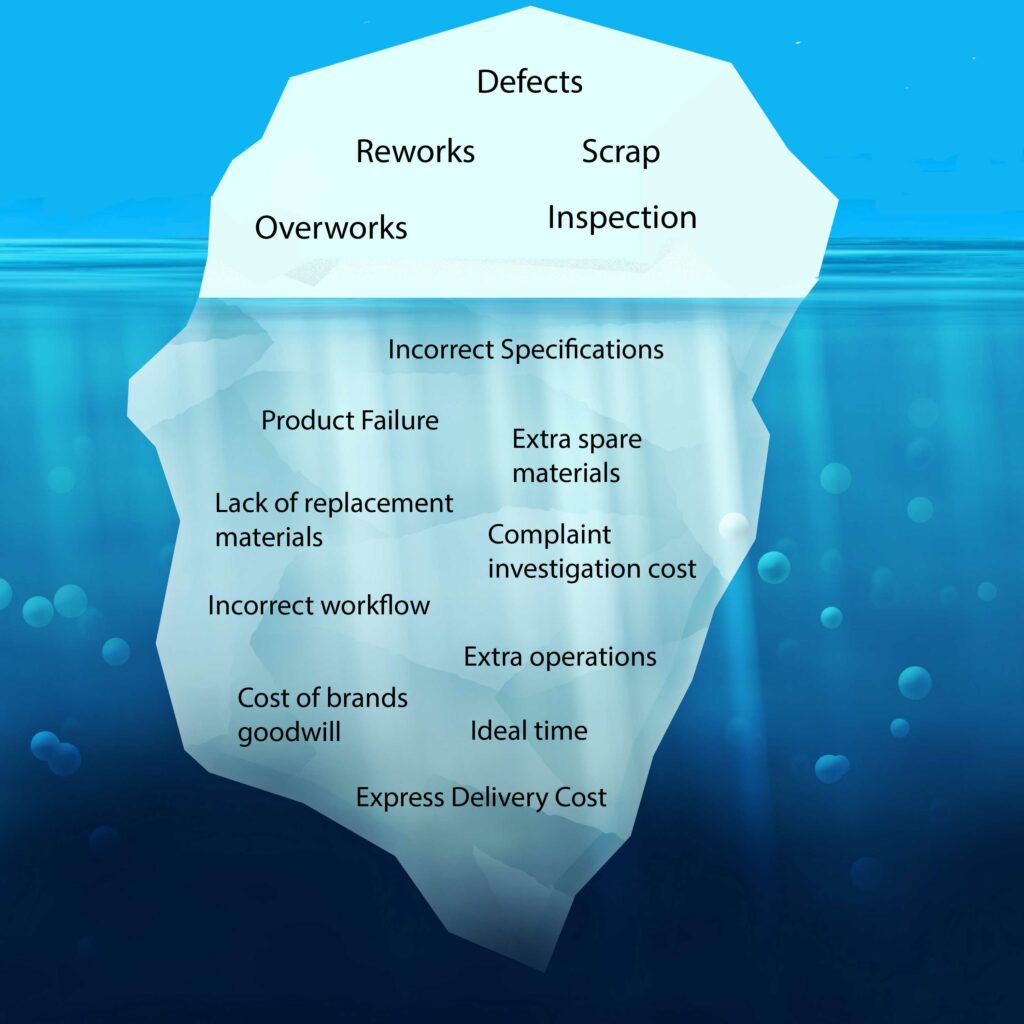

One main challenge today is to minimize the Cost of Poor Quality.

COPQ is the cost generated as a result of producing a defective product.

According to WTO 2018 report, there is a 12.61 % Defect Rate.

This equates to USD$ 104.9 Billion of wasted costs!

Small Order Quantity with many SKUs

Consumer’s preferences change rapidly

Fast fashion with customization sourcing trend

Increasing complexity of style management

Countless Quality Tests & Inspections

Buyers’ high demand of requirements

More and more inspections required due to increasing style varieties

Poor quality management in factory

Resulting in High Defect Rates

High Costs for Inspections

Labour intensive processes

Inefficient manual processes

Internal & external re-inspections

Time consuming

Stress on Shipment delays

Short production lead time

Low visibility of factory production and quality control

Late Shipment penalties / air shipment due to defect and rework

Liabilities on recalls

Our goal is to help with your pain points.

Contact us now for a free consultation to see which products would best suit your needs.